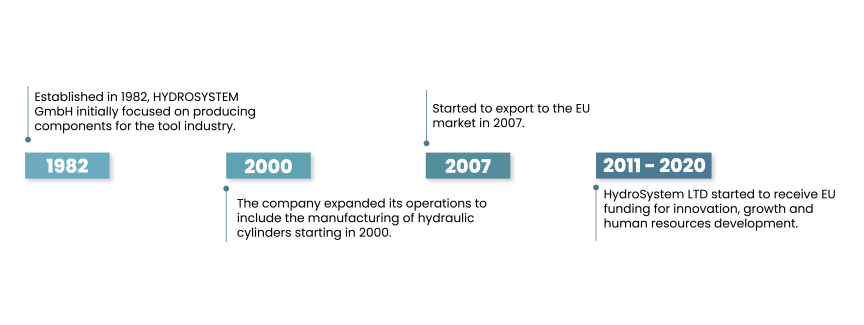

“Established in 1982, HYDROSYSTEM GmbH initially focused on producing components for the tool industry. The company expanded its operations to include the manufacturing of hydraulic cylinders starting in 2000.

HYDROSYSTEM GmbH boasts a staff of 160 skilled professionals in the field of metal-processing, including 20 highly qualified engineers. These engineers specialize in the design and construction of hydraulic cylinders, technological support of production, and programming of CNC machines. There is a special team responsible for marketing, as well as account management for clients and suppliers.”

We pride ourselves on a rich history that informs our innovative approaches, ensuring we remain at the forefront of the industry.

HYDROSYSTEM is a fast-growing and innovative company, specialized in the design and manufacture of hydraulic cylinders. We continuously improve and invest in new equipment and technologies, striving to push the boundaries of what’s possible in our field.

We are confident that we can become your most reliable supplier of hydraulic cylinders!”

Throughout its development, HYDROSYSTEM has become a specialist in the production of hydraulic and pneumatic cylinders, along with spare parts for these systems. Our product range includes double-acting, single-acting, and telescopic outrigger cylinders, commonly known as support cylinders.

We take pride in our manufacturing process, which is highly adaptable to meet specific customer needs. Our cylinders are meticulously crafted either according to our own expertly designed documentation or based on designs provided by our customers. This flexibility ensures that we can tailor our products to fit the precise requirements of each client, guaranteeing satisfaction and optimal performance.

Moreover, our commitment to quality and precision in manufacturing is matched by our dedication to customer collaboration. We work closely with clients to agree upon the best designs, ensuring that each product we manufacture aligns perfectly with their specifications and application needs.

HYDRAULIC CRUTCH

1. Nominal pressure: 150 bar

2. Stroke: 250 ± 3 mm

3. Hydraulic Crutch Types and Dimensions: – Types and Dimensions (d x D x C):

– 85 x 102 x 230 mm (446.1.00.00, 342.1.00.00)

4. Hydraulic Hand Pump (HHP 25):

– Flow: 25 cc – Pressure: 280 bar (Exercise), 350 bar (Max)

5. Hydraulic Hand Pump Tank Capacities and Pressures:

– Types: HOT 1, HOT 2, HOT 3, HOT 5, HOT 7 –

Tank capacities: 1L, 2L, 3L, 5L, 7L –

Pressures: – A: 90 bar , B: 120 bar , C: 150 bar

– D: Varies by type (100-195 bar)

-E: Varies by type (120-269 bar)

Construction and Heavy Machinery

Waste Management

Aerospace

Automotive

Agriculture

Civil Engineering

Our hydraulic cylinders and devices are integral components in a wide array of industries, owing to their versatility and efficiency in creating powerful, controlled movements. These products find extensive application in the agricultural sector, enhancing the functionality of various types of machinery such as tractors, harvesters, and irrigation systems. In the realm of material handling, they are crucial in the operation of forklift trucks, offering precision and strength for heavy lifting tasks.

Furthermore, our hydraulic solutions play a vital role in the manufacturing industry, especially in presses where they provide the necessary force for molding and shaping materials. In the construction sector, particularly in road building, our products are essential for the smooth operation of machines like bulldozers, excavators, and asphalt pavers.

Additionally, these hydraulic elements are employed in mining equipment, aiding in excavation and material handling under challenging conditions. They are also key in waste management machinery, contributing to efficient recycling and waste processing operations.

Each industry benefits from the reliability and high-performance capabilities of our hydraulic products, where movement and force are achieved through high-pressure hydraulic elements. Our commitment to quality and innovation ensures that these industries can rely on our products for their critical operations, driving efficiency and productivity in their respective fields.

equipped with state-of-the-art programmable lathes and CNC machines, reflecting our commitment to utilizing advanced technology in our manufacturing processes. This modern machinery enables us to achieve high precision and efficiency in producing our hydraulic products.

Additionally, the company places a strong emphasis on quality control. Our excellent control facility is designed to ensure that every product meets the highest standards of quality and performance. We prioritize both the quantity and accuracy of our deliveries, understanding that timely and correct fulfilment of orders is crucial to our clients. This focus on reliability and precision in both manufacturing and distribution underlines HYDROSYSTEM’s dedication to customer satisfaction and excellence in all aspects of our operations.

partners worldwide!

We proudly export over 95% of our production to various countries within the European Union, including Germany, France, Italy, the Netherlands, and Spain, among others. Our extensive customer base in these regions stands as a testament to our commitment to quality and international appeal.